ARTICLE AD BOX

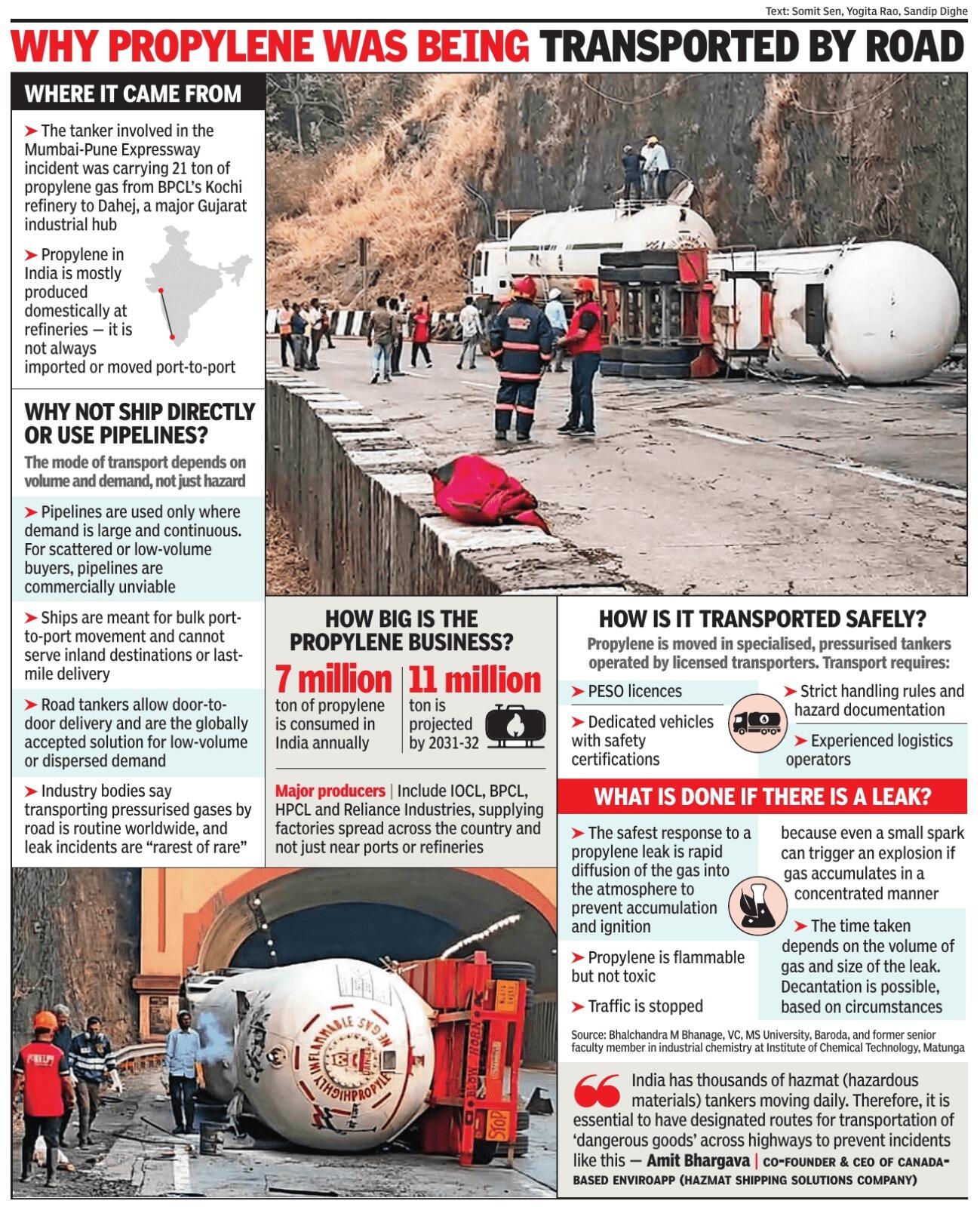

PUNE: The overturning of a propylene gas tanker on the Mumbai–Pune Expressway has triggered questions over why a highly flammable chemical was being transported by road. Experts and industry officials say such movement is routine worldwide and driven by demand patterns, logistical constraints and the absence of viable alternatives such as pipelines or shipping for inland deliveries. The tanker involved in Tuesday’s incident was carrying 21 tonnes of propylene gas from BPCL’s Kochi refinery to Dahej, a major industrial hub in Gujarat. Propylene in India is largely produced domestically at refineries and supplied to factories spread across the country, many of which are located far from ports or pipeline networks. According to industry sources, the choice of transport depends primarily on volume and demand, not just the hazardous nature of the material.

Pipelines are commercially viable only where demand is large and continuous. For scattered or low-volume buyers, laying pipelines is impractical. Shipping, meanwhile, is limited to bulk port-to-port movement and cannot serve inland or last-mile destinations.

As a result, road tankers remain the globally accepted solution for door-to-door delivery of pressurised gases such as propylene. Industry bodies maintain that such transportation is routine across countries and that leak incidents are rare.

India’s propylene market is sizeable and growing. The country currently consumes around 7 million tonnes of propylene annually, with demand projected to rise to 11 million tonnes by 2031–32. Major producers include IOCL, BPCL, HPCL and Reliance Industries, which supply manufacturing units across multiple states. To minimise risk, propylene is transported in specialised, pressurised tankers operated by licensed transporters.

These vehicles require approvals from the Petroleum and Explosives Safety Organisation (PESO), along with dedicated safety-certified equipment, strict hazard documentation and experienced logistics operators. Experts say emergency response protocols are designed to prevent gas accumulation in the event of a leak. “The safest response to a propylene leak is rapid diffusion of the gas into the atmosphere to prevent ignition,” said Bhalchandra M Bhange, vice-chancellor of MS University, Baroda, and a former senior faculty member at the Institute of Chemical Technology, Matunga.

While propylene is highly flammable, it is not toxic, he noted. Traffic is typically halted during such incidents because even a small spark can trigger an explosion if gas accumulates in a concentrated area. The time taken to control a leak depends on the volume of gas and the size of the breach, and in some cases, decantation into empty tankers may be required. Amit Bhargava, co-founder and CEO of Canada-based EnviroApp, said the incident underlined the need for better regulation of hazardous cargo movement.

“India has thousands of hazardous material tankers moving daily. It is essential to have designated routes for transporting dangerous goods across highways to prevent incidents like this,” he said. While experts stress that transporting propylene by road is unavoidable under current infrastructure constraints, they warn that rising volumes of hazardous material on highways make stronger safety protocols, designated routes and faster emergency response systems increasingly critical to prevent future accidents from turning into major disasters.

8 hours ago

5

8 hours ago

5

English (US) ·

English (US) ·