ARTICLE AD BOX

Lucknow has witnessed many histories. Whispers of nawabs and poets, of rebellion and resilience, have seeped into its very essence. The Ganges, not far away, flowing steadily southward, is bearing witness to the birth of something unstoppable—a supersonic force that is redefining the skies, seas, and soils of a nation on the cusp of global reckoning.

This is not a factory; it is a crucible. Sprawling over 200-acre canvas on the city’s outskirts, the state-of-the-art BrahMos Aerospace Integration and Testing Facility , India’s most formidable conventional deterrent—the supersonic BrahMos cruise missile—is being born, assembled, and given its wings.

The Making of a Supersonic Citadel

The journey began in 2018 when the Uttar Pradesh government offered 200 acres of prime land along the Lucknow-Kanpur highway as part of the Uttar Pradesh Defence Industrial Corridor (UPDIC).

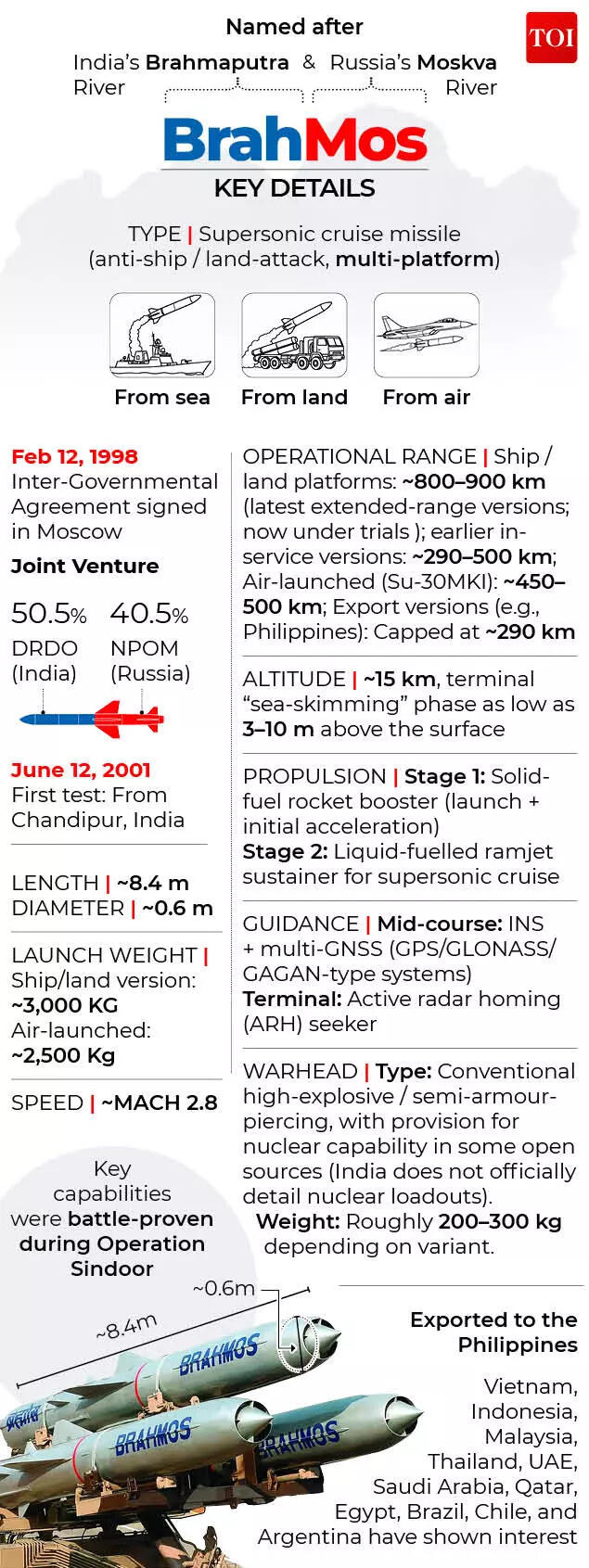

BrahMos Aerospace Private Limited (BAPL), the Indo-Russian joint venture between DRDO and Russia’s NPO Mashinostroyeniya, had outgrown its Hyderabad, Thiruvananthapuram, Pilani and Nagpur’s production and system integration units.

Orders were pouring in: the Indian navy wanted more ship- and submarine-launched missiles, the air force was integrating the air-launched version on forty Su-30MKIs, the army needed extended-range land variants, and — most importantly — export enquiries were turning into hard contracts.

The Philippines had already taken delivery of its first battery in 2024 under a 375 million USD deal. Indonesia, Vietnam, Malaysia, Argentina, Egypt, Saudi Arabia and the UAE were in various stages of negotiation. By 2025 BrahMos Aerospace had firm orders for over 800 missiles in the next five years. Existing facilities simply could not cope.So, Lucknow happened.Built at a cost of around Rs 380 crore, the new campus is a city within a city: massive integration halls, a booster production block, a warhead mating facility, long high-speed sled track for subsystem validation, and an environmentally controlled pre-dispatch inspection bay that looks more like a spacecraft cleanroom than a weapons factory.

Every variant of the BrahMos family — from the original 290 km land and ship versions to the 600 km extended-range and the lighter BrahMos-NG under development — will roll out from here.

Inauguration And Production

This year on May 11, Defence Minister Rajnath Singh virtually inaugurated the facility, the crown jewel of the Uttar Pradesh Defence Industrial Corridor (UPDIC), was conceived with a singular, powerful objective: to become the epicentre for meeting the soaring domestic and international demand for the BrahMos weapon system.

“The state-of-the-art BrahMos Integration and Testing facility in Lucknow has been set up to cater to the growing demand for BrahMos weapon systems in the domestic and international markets. Its strategic location, a logistical advantage with seamless access to national freight corridors, ensures that the fury assembled here can be dispatched with efficiency to any frontier,” said an official source.

On October 18, the Defence Minister in presence of Chief Minister Uttar Pradesh Yogi Adityanath, Department of Defence R&D and Chairman DRDO Samir V Kamat, and DG BrahMos Jaytirth R Joshi, flagged off the first batch of missiles to the Indian Armed Forces, sleek and lethal in their transporter canisters, it marked a paradigm shift.

For decades, defence manufacturing was perceived as the preserve of coastal or traditional industrial hubs. Lucknow’s roar announced a new geography of power.What’s inside the facility

- Large integration halls

- A booster production block

- A warhead mating facility

- A long high-speed sled track for subsystem validation

- An environmentally controlled pre-dispatch inspection bay (likened to a cleanroom)

The aim: produce and support multiple BrahMos variants—from legacy 290 km versions to extended-range and the under-development BrahMos-NG.

The Human Engine Behind the Ramjet

BrahMos Aerospace employs around 300-500 people directly at the Lucknow unit today, but the ripple effect is staggering.A senior BrahMos official explained: “A missile is an extremely complex system that draws on diverse industries, advanced materials, chemicals, rubber, electronics, mechanical subsystems, precision machining, welding, and more. Today, BrahMos works with over 200 private and public-sector industry partners across India who supply components, sub-assemblies, off-the-shelf items, and specialised fixtures to build the complete weapon system.

"

"With demand rising sharply, both from the Indian armed forces and export orders, we need to significantly diversify and expand our supply chain. The new Lucknow facility, located at the heart of the Uttar Pradesh Defence Corridor, offers the ideal platform to onboard many more MSMEs and manufacturers in the region. Proximity will enable tighter project monitoring, faster iteration, and even higher quality standards," added the officialThe official added that the company is actively scouting new vendors in and around Lucknow to support production targetsFurther, the human capital powering this enterprise is as meticulously curated as the technology.

BrahMos Aerospace, as a world-class defence entity, adheres to a creed of pure meritocracy.

“We recruit highly skilled professionals involved in designing a very high-end weapon system. We adhere to the same standards for Lucknow,” stated the official source. There is no quota for locality; excellence is the only passport.For a young engineer dreaming of contributing to missile technology, the path is clear and demanding.A stellar academic foundation in aerospace, mechanical, electronics, or computer science is the entry ticket. The recruitment funnel—through national vacancies and elite campus placements—involves rigorous technical assessments, multiple interview rounds, and stringent security clearances. The promise of “huge employment opportunities” is real, but they are opportunities earned in the most competitive arena.

The numbers that matter

- Annual production target from Lucknow unit: 80–100 missiles.

- Expected revenue contribution by FY 2027-28: Rs 3,000 crore

- GST from a single missile: Rs 8 crore. On October 18, DG BrahMos, Jaytirth R Joshi handed over the GST bill and cheque of around Rs 40 crore to the UP Chief Minister, symbolising revenue generation for the state.

- Export pipeline: Negotiations ongoing with around dozen countries

- Indigenous content in current production block: 83%, moving to 85% in 2026, which includes fully indigenous titanium castings (PTC Industries, Lucknow), solid rocket boosters, airframe (L&T, Godrej), avionics (HAL & Data Patterns), and inputs from 200+ Indian MSMEs.

The next frontier

On land and ship versions, instead of three missiles, six or eight can be packed, thanks to the reduced size. This approach aims to maintain effectiveness while increasing numbers and reducing costs, ensuring steady supply to the armed forces.

The Lucknow facility will be its birthplace.An official source summed it up: “The BrahMos Integration and Testing Facility is an ultra-modern manufacturing unit designed for the production, assembly, and integration of all BrahMos variants, including the advanced air-launched version. It will also serve as the hub for the next-generation BrahMos in the foreseeable future.”

1 hour ago

6

1 hour ago

6

English (US) ·

English (US) ·